Electrodes Are Coated With . welding electrode coating types. coated electrodes help by providing a focused arc that melts through the metal more efficiently, allowing for better. discover the four main types of electrode flux coatings and their impact on welding performance. From rutile and cellulosic to. From rutile and cellulosic to. electrode coating is the mixture of chemicals, minerals, and metallic alloys applied to the core wire. discover the four main types of electrode flux coatings and their impact on welding performance. the main reason welding electrodes are coated is to protect them from reacting with the atmosphere. This is important because welding requires extremely. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc.

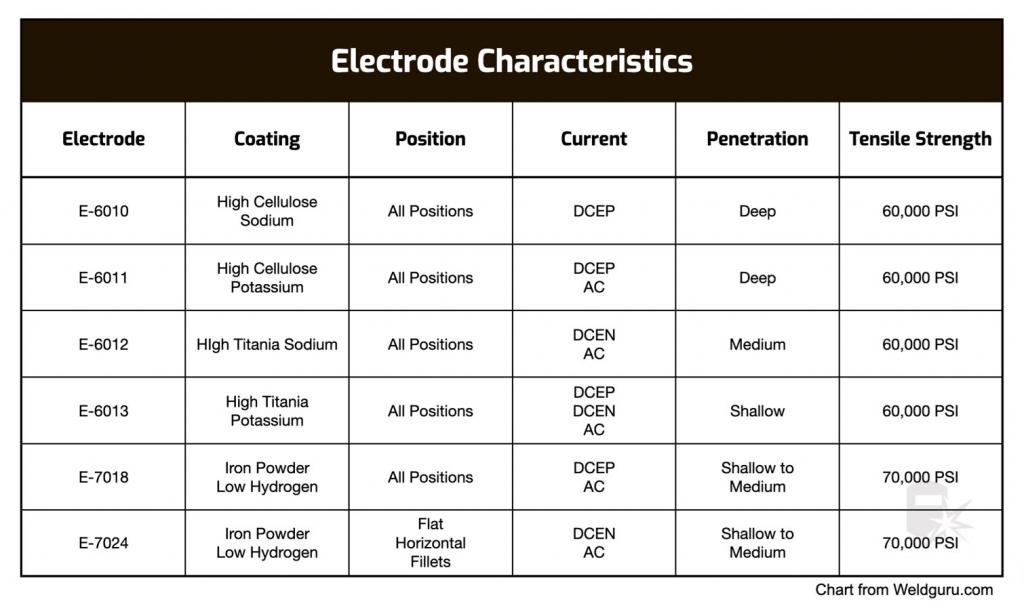

from weldguru.com

coated electrodes help by providing a focused arc that melts through the metal more efficiently, allowing for better. electrode coating is the mixture of chemicals, minerals, and metallic alloys applied to the core wire. From rutile and cellulosic to. discover the four main types of electrode flux coatings and their impact on welding performance. discover the four main types of electrode flux coatings and their impact on welding performance. From rutile and cellulosic to. welding electrode coating types. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. This is important because welding requires extremely. the main reason welding electrodes are coated is to protect them from reacting with the atmosphere.

Welding Electrode Chart and Selection Weld Guru

Electrodes Are Coated With the main reason welding electrodes are coated is to protect them from reacting with the atmosphere. From rutile and cellulosic to. discover the four main types of electrode flux coatings and their impact on welding performance. This is important because welding requires extremely. coated electrodes help by providing a focused arc that melts through the metal more efficiently, allowing for better. discover the four main types of electrode flux coatings and their impact on welding performance. electrode coating is the mixture of chemicals, minerals, and metallic alloys applied to the core wire. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. From rutile and cellulosic to. the main reason welding electrodes are coated is to protect them from reacting with the atmosphere. welding electrode coating types.

From www.global.toshiba

SkinCoated Electrode SCiB™ Rechargeable battery Toshiba Electrodes Are Coated With This is important because welding requires extremely. coated electrodes help by providing a focused arc that melts through the metal more efficiently, allowing for better. From rutile and cellulosic to. welding electrode coating types. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. From rutile and cellulosic to. discover the. Electrodes Are Coated With.

From weldingtrends.com

Why Welding Electrodes Are Coated? Electrodes Are Coated With welding electrode coating types. This is important because welding requires extremely. electrode coating is the mixture of chemicals, minerals, and metallic alloys applied to the core wire. the main reason welding electrodes are coated is to protect them from reacting with the atmosphere. From rutile and cellulosic to. coated electrodes help by providing a focused arc. Electrodes Are Coated With.

From blog.thepipingmart.com

AWS Class E316/316H16 Coated Electrodes Composition, Properties, and Electrodes Are Coated With electrode coating is the mixture of chemicals, minerals, and metallic alloys applied to the core wire. discover the four main types of electrode flux coatings and their impact on welding performance. This is important because welding requires extremely. the main reason welding electrodes are coated is to protect them from reacting with the atmosphere. discover the. Electrodes Are Coated With.

From www.youtube.com

CAN WE SELECT ELECTRODE BY COLOR OF COATING? WHY WE NEED FLUX COATING Electrodes Are Coated With The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. discover the four main types of electrode flux coatings and their impact on welding performance. From rutile and cellulosic to. the main reason welding electrodes are coated is to protect them from reacting with the atmosphere. electrode coating is the mixture. Electrodes Are Coated With.

From blog.thepipingmart.com

3 Types of Electrode Coating Electrodes Are Coated With The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. electrode coating is the mixture of chemicals, minerals, and metallic alloys applied to the core wire. coated electrodes help by providing a focused arc that melts through the metal more efficiently, allowing for better. From rutile and cellulosic to. welding electrode. Electrodes Are Coated With.

From ceztjhyn.blob.core.windows.net

Types Of Electrodes In Welding at Chelsie Benn blog Electrodes Are Coated With coated electrodes help by providing a focused arc that melts through the metal more efficiently, allowing for better. From rutile and cellulosic to. electrode coating is the mixture of chemicals, minerals, and metallic alloys applied to the core wire. From rutile and cellulosic to. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes. Electrodes Are Coated With.

From www.indiamart.com

Rutile Coated Electrodes For Mild Steels Mild Steel Medium Heavy Electrodes Are Coated With coated electrodes help by providing a focused arc that melts through the metal more efficiently, allowing for better. This is important because welding requires extremely. the main reason welding electrodes are coated is to protect them from reacting with the atmosphere. welding electrode coating types. From rutile and cellulosic to. electrode coating is the mixture of. Electrodes Are Coated With.

From www.researchgate.net

Comparison of gold coated electrodes and PEDOTPSS coated electrodes Electrodes Are Coated With the main reason welding electrodes are coated is to protect them from reacting with the atmosphere. electrode coating is the mixture of chemicals, minerals, and metallic alloys applied to the core wire. discover the four main types of electrode flux coatings and their impact on welding performance. discover the four main types of electrode flux coatings. Electrodes Are Coated With.

From www.weldinghandbook.com

Welding Electrodes Coatings and Classifications The Welding Handbook Electrodes Are Coated With coated electrodes help by providing a focused arc that melts through the metal more efficiently, allowing for better. discover the four main types of electrode flux coatings and their impact on welding performance. electrode coating is the mixture of chemicals, minerals, and metallic alloys applied to the core wire. discover the four main types of electrode. Electrodes Are Coated With.

From www.researchgate.net

Scheme of the electrodes coated with two polyelectrolyte layers Electrodes Are Coated With electrode coating is the mixture of chemicals, minerals, and metallic alloys applied to the core wire. From rutile and cellulosic to. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. From rutile and cellulosic to. This is important because welding requires extremely. welding electrode coating types. discover the four main. Electrodes Are Coated With.

From blog.csiro.au

Diamond coated electrodes are forever CSIROscope Electrodes Are Coated With welding electrode coating types. coated electrodes help by providing a focused arc that melts through the metal more efficiently, allowing for better. discover the four main types of electrode flux coatings and their impact on welding performance. the main reason welding electrodes are coated is to protect them from reacting with the atmosphere. From rutile and. Electrodes Are Coated With.

From blog.thepipingmart.com

AWS Class E9015B9 Coated Electrodes Composition, Properties, and Uses Electrodes Are Coated With discover the four main types of electrode flux coatings and their impact on welding performance. This is important because welding requires extremely. From rutile and cellulosic to. welding electrode coating types. the main reason welding electrodes are coated is to protect them from reacting with the atmosphere. coated electrodes help by providing a focused arc that. Electrodes Are Coated With.

From weldguru.com

Welding Electrode Chart and Selection Weld Guru Electrodes Are Coated With the main reason welding electrodes are coated is to protect them from reacting with the atmosphere. This is important because welding requires extremely. From rutile and cellulosic to. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. coated electrodes help by providing a focused arc that melts through the metal more. Electrodes Are Coated With.

From blog.thepipingmart.com

AWS Class E259416 Coated Electrodes Composition, Properties, and Uses Electrodes Are Coated With This is important because welding requires extremely. From rutile and cellulosic to. welding electrode coating types. discover the four main types of electrode flux coatings and their impact on welding performance. electrode coating is the mixture of chemicals, minerals, and metallic alloys applied to the core wire. The coating provides protection for the molten metal, influences the. Electrodes Are Coated With.

From www.weldingandndt.com

Welding electrodes Understanding the SMAW electrode symbols Welding Electrodes Are Coated With discover the four main types of electrode flux coatings and their impact on welding performance. coated electrodes help by providing a focused arc that melts through the metal more efficiently, allowing for better. the main reason welding electrodes are coated is to protect them from reacting with the atmosphere. welding electrode coating types. From rutile and. Electrodes Are Coated With.

From ceidbuhx.blob.core.windows.net

Types Of Electrode Coating at Gloria Faulkner blog Electrodes Are Coated With From rutile and cellulosic to. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. This is important because welding requires extremely. discover the four main types of electrode flux coatings and their impact on welding performance. From rutile and cellulosic to. welding electrode coating types. electrode coating is the mixture. Electrodes Are Coated With.

From techstory.in

Tesla Giga Berlin's 4680 battery cells with DryElectrode coating Electrodes Are Coated With coated electrodes help by providing a focused arc that melts through the metal more efficiently, allowing for better. electrode coating is the mixture of chemicals, minerals, and metallic alloys applied to the core wire. From rutile and cellulosic to. welding electrode coating types. the main reason welding electrodes are coated is to protect them from reacting. Electrodes Are Coated With.

From www.mtixtl.com

Automatic Battery Electrode Coating System with Slurry Feeder, Coater Electrodes Are Coated With This is important because welding requires extremely. electrode coating is the mixture of chemicals, minerals, and metallic alloys applied to the core wire. The coating provides protection for the molten metal, influences the weld’s characteristics, and stabilizes the arc. welding electrode coating types. coated electrodes help by providing a focused arc that melts through the metal more. Electrodes Are Coated With.